-

Hot

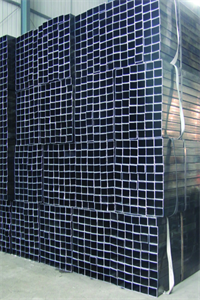

hot sell Black Steel Pipe, ERW low carbon hollow section tube

Black annealed steel tube is also called cold rolled steel pipe and tubes,it is also called hollow secion it is one of the most common steel tubes. with the ERW tecnical , Low carbon material , If cold rolled steel is heated to annealing temperature, the surface color turns black due to high temperature contact with air, it is called black annealed steel pipes. Its surface has not been polished so it is black. The physical properties become soft, convenient for further welding into steel pipe. Common hardness 57HRB, can also be reduced to different hardness according to need.

Send Email Details -

Hot

China Black annealed square/round/rectangular hollow section steel pipe steel tube MS ERW steel pipe steel tube carbon steel pipe steel tube

China Black annealed square/round/rectangular hollow section steel pipe steel tube MS ERW steel pipe steel tube carbon steel pipe steel tube , The pipes ductility usually good it can bend 90 degree, so it use more widely, the hardness less usually 40-55, this not play good than hot rolled, it usually used on , fruniture, fence, building material , Oil/Gas Drilling, Food/Beverage/Dairy Products, Machinery Industry, Chemical Industry, Mining, Construction & Decortion. and so on

Send Email Details -

Hot

Cold rolled welded square, rectangular steel pipe hollow section prefab house steel tube

The cold-rolled welded pipe has high precision, uniform wall thickness, high brightness inside the pipe surface (the surface brightness of the steel pipe is determined by the surface grade of the steel plate), and can be arbitrarily fixed. In high precision, medium and low pressure fluid applications reflect its economy and aesthetics. the cold rolled use widely, the pipes used for fence pipe, furniture, tools, building material and so on. they are surface smoothly , and black color.

Send Email Details -

Hot

Manufacturer ERW Welded Steel Pipe Iron Black Tube Gi Galvanized Steel Pipe For Construction

ERW is Electric Resistance welding,ERW pipe and submerged arc welding pipe welding method is significantly different, The pressure welding method without filler metal is adopted, and no other components are filled in the welding seam. By the skin effect and proximity effect of high-frequency current, the plate edge is instantly heated to the welding temperature, and the weld with forged structure is formed by extrusion roller. High quality steel pipe requires weld line or off-line heat treatment to refine the weld zone. The weld line of high quality ERW welded pipe can reach the same toughness level as the base metal, which cannot be achieved by submerged arc welding process

Send Email Details -

Hot

Q195 Cold Rolled steel hollow section Pipes for fence

The cold-rolled welded pipe has high precision, uniform wall thickness, high brightness inside the pipe surface (the surface brightness of the steel pipe is determined by the surface grade of the steel plate), and can be arbitrarily fixed. In high precision, medium and low pressure fluid applications reflect its economy and aesthetics. The main differences between cold rolling and cold rolling are: 1. Local buckling occurs in the section of cold-rolled shaped steel, so as to make full use of the bearing capacity of the bar after buckling; Local buckling of hot rolled section is not allowed. 2. The causes of residual stress in hot rolled steel and cold rolled steel are different, so the distribution on section is also very different. The residual stress distribution on cold-formed thin-wall section is curved, while that on hot-bound or welded section is thin film. 3. The free torsion stiffness of hot rolled section is higher than that of cold rolled section, so the torsion resistance of hot rolled section is better than that of cold rolled section. Standard : GB/T3091-2001 * ASTM A53-1996 * BS1387-1985 * BS4568-1970 * GB/T6728-2002

Send Email Details